the rockwell test measures hardness as a function of what|rockwell hardness test theory : trader How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart. How to Calibrate a Rockwell Hardness Tester. What is the Standard for . WEBIf you purchased a game from the Epic Games Store website, it’ll be available for download in the Library section of your Epic Games Launcher. If you don’t already have the Epic Games Launcher, you can download it here by clicking the Download button in the top right corner of the page.

{plog:ftitle_list}

Zacarias Portal May 19, 2022 · ESTUDANTE DE 14 ANOS SOFRE BULLYING NA ESCOLA E TENTA SUICÍDIO SE JOGANDO DA CAIXA D'ÁGUA NA FEIRA DO .

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the .The Rockwell hardness test method is a simple process that uses a diamond cone with a round tip for harder materials and a hardened steel ball indenter for softer ones. With every test, two loads are applied to the test subject.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .How Does the Rockwell Hardness Test Work? How to Use a Rockwell Hardness Tester? Interpreting the Results with a Rockwell Hardness Test Chart. How to Calibrate a Rockwell Hardness Tester. What is the Standard for .

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test .

The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in practice. Looking into the features and functions of hardness testing machines, some key attributes have stood out from reviews and specifications from top industry websites. Rockwell Hardness Tester: It has an automatic .What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for .

The Rockwell hardness test is an essential tool in material science, offering a fast and trustworthy way to measure how hard materials are, with a special focus on metals. . ASTM G65 Dry Sand Abrasion Testing ASTM G65 measures the resistance of metallic materials to abrasion using the dry sand/rubber wheel apparatus. The quality, durability .materials testing Rockwell hardness tester Brinell hardness test . this area is a function of the ball diameter and the depth of the indentation. . The Shore scleroscope measures hardness in terms of the elasticity of the material. The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.The Rockwell hardness test method has a whopping 30 hardness scales defined by the indenter and the two loads. A Rockwell hardness value is a combination of the numerical hardness number and the Rockwell hardness scale letters preceded by letters HR. For example, a hardness value of 70 on Rockwell scale A is written 70 HRA.

The Rockwell hardness test continues to be applied as a tool for assessing the properites of a product while the tolerances on the acceptable material hardness have become tighter and tighter. Adhering to good practice procedures when performing Rockwell hardness measurements and calibrations is a beneficial step to reducing measurement errors.

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.The selection of a scale can be somewhat arbitrary in certain hardness tests. For instance, in the Rockwell hardness test, hardness values range from 0 to 100 based on indentation depth, but each test method defines its scale uniquely.Phase II Hardness Testers accurately measure hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120° diamond indentor in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB 25-100). Very hard materials are tested using a 120° diamondIndenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to .

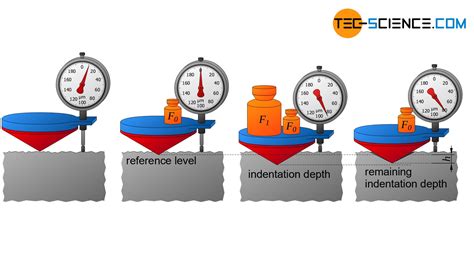

This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).While both Brinell and Rockwell hardness tests measure the hardness of a material, there are some key differences between the two methods. One significant difference is the shape of the indenter used in each test. The Brinell hardness test uses a spherical indenter, while the Rockwell hardness test uses either a diamond cone or steel ball indenter. In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm .The Phase II 900-410 Digital Rockwell Hardness Tester with Touchscreen Functions can be used to measure Rockwell hardness scales and quickly convert the hardness value into Rockwell, Superficial Rockwell, Brinell, and .

Hardness Methods: The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. Rockwell Hardness The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and yThe Rockwell M hardness test is used to measure the hardness of a wide range of materials. For example, metals, plastics, ceramics, and composite materials (such as fiberglass and carbon fiber). It ensures the meeting of the required quality standards of the materials.

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.

Converting Rockwell hardness to Brinell hardness is challenging because they measure hardness differently. It requires using empirical correlations or conversion tables, and the relationship isn’t linear. The best approach is to consult specific conversion resources for the particular materials and conditions you are working with. Rockwell to Brinell Hardness .

The Rockwell hardness test is performed primarily through a test force, more commonly known as a minor load or preload. . The most widely used indenter is the diamond cone, which can measure the hardness of carbides and steel at 120 degrees. Other materials, especially softer ones, are gauged with the use of tungsten carbide rounds. The test .

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20-70). Soft materials are tested using a 1/16" carbide ball indenter in the B-scale (HRB 25-100). Very hard materials are tested using a 120 diamond indenter in

The Rockwell hardness test measures a number which depends on the difference in the depth of an indentation made by two loads, a minor load followed by a major load. There are different scales for the Rockwell hardness test. For example, the commonly used Rockwell C test uses a minor load of 10 kg, followed by a major load of 150 kg.

Fixed Online Gas Detector

A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a measuring transducer. The DuraJet, ZHR Touchscreen and ZHR8150CL models are software controlled hardness testing machines with automatic .ROCKWELL HARDNESS TESTING MACHINES TEST EQUIPMENT HR-300/400/500 SERIES AND SEISMOMETERS. Rockwell Hardness Testing Machines to suit . Continuous test function (for specimens with the same thickness) Cylindrical correction, spherical correction, offset correction, multi-point correction functions .The 3831Digital Rockwell Hardness Tester can be used directly to measure the most popular regular Rockwell hardness scales and it can quickly convert that hardness value into HB, HV, HLD, HK and many other scales. Loaded with many useful features such as ultra precise results, wide measuring range, scale and test force selectable, automatic .

rockwell hardness testing method

rockwell hardness tester least count

Resultado da The latest tweets from @rodrigobrand_

the rockwell test measures hardness as a function of what|rockwell hardness test theory